How Does a Solar Mid Clamp Support Long-Term PV System Stability?

2025-12-31

Article Abstract

Solar Mid Clamp is a critical mechanical fastening component used in photovoltaic mounting systems to secure adjacent solar panels along shared module edges. This article provides a comprehensive, technically driven examination of Solar Mid Clamp design logic, material parameters, dimensional standards, installation methodology, and compatibility with modern PV structures. Through structured analysis, real-world engineering considerations, and common technical questions, the content explains how Solar Mid Clamps contribute to system stability, compliance, and scalability in global solar installations.

Table of Contents

- How Is a Solar Mid Clamp Defined in PV Mounting Systems?

- How Do Technical Parameters Influence Solar Mid Clamp Performance?

- How Should Solar Mid Clamps Be Selected and Installed for Different Applications?

- How Is the Role of Solar Mid Clamps Evolving in Future PV Systems?

Outline

- Definition and functional positioning of Solar Mid Clamp

- Engineering parameters and material specifications

- Selection logic, installation standards, and compatibility

- Industry evolution, standardization, and brand perspective

How Is a Solar Mid Clamp Defined in PV Mounting Systems?

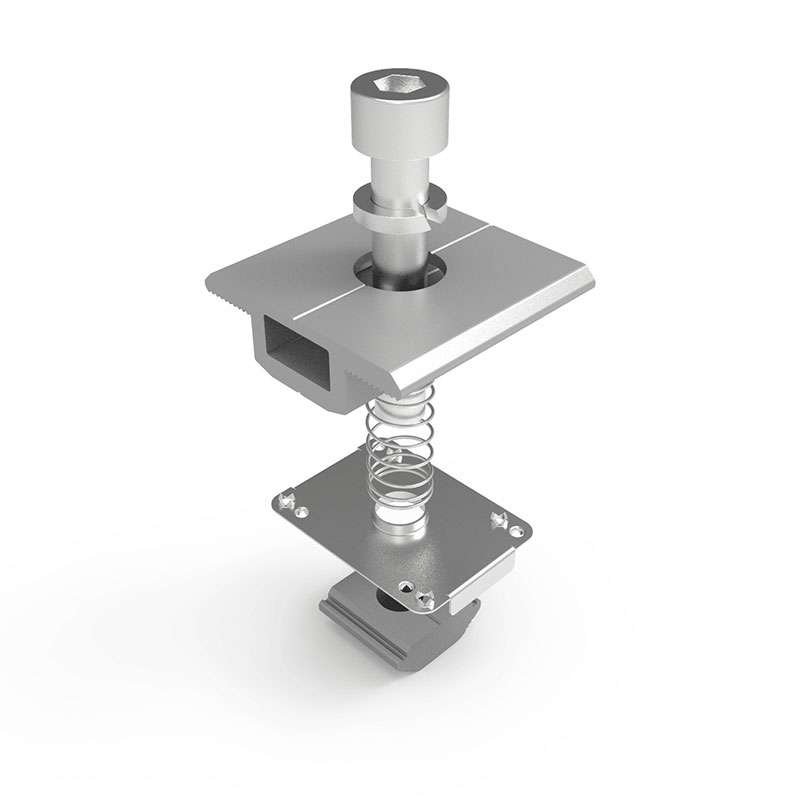

A Solar Mid Clamp is a fastening component installed between two adjacent photovoltaic modules to secure them onto a mounting rail. Unlike end clamps, which terminate the outer edges of a module array, mid clamps provide continuous clamping force along internal panel boundaries, ensuring uniform load distribution across the array.

In utility-scale, commercial, and residential PV installations, the Solar Mid Clamp plays a decisive role in maintaining module alignment, resisting wind uplift, and preserving frame integrity over long service lifecycles. Its geometry and preload force are engineered to accommodate standardized module frame thicknesses while minimizing micro-movement that may lead to long-term fatigue.

How Do Technical Parameters Influence Solar Mid Clamp Performance?

The mechanical performance of a Solar Mid Clamp is determined by its material composition, surface treatment, dimensional tolerances, and fastening interface. Precision in these parameters directly affects structural safety and installation efficiency.

| Parameter | Specification Range | Engineering Relevance |

|---|---|---|

| Material | AL6005-T5 / AL6063-T6 / Stainless Steel 304 | Determines corrosion resistance and tensile strength |

| Surface Treatment | Anodized ≥10μm / Natural Finish | Improves environmental durability |

| Module Thickness Compatibility | 30mm / 35mm / 40mm / Custom | Ensures correct clamping pressure |

| Fastener Type | M8 Stainless Steel Bolt & Nut | Controls torque and preload consistency |

| Wind Load Rating | ≥2400 Pa | Supports compliance with IEC standards |

These parameters collectively ensure that the Solar Mid Clamp functions as a load-transfer interface between the solar module and mounting rail, rather than as a standalone fastener.

Solar Mid Clamp Common Questions and Answers

Q: How does a Solar Mid Clamp differ from an end clamp?

A: A Solar Mid Clamp is positioned between two modules and secures both simultaneously, while an end clamp secures only the outermost module edge. Mid clamps enable uniform spacing and continuous load sharing across arrays.

Q: How is proper torque determined for Solar Mid Clamp installation?

A: Torque values are defined by bolt grade, clamp material, and rail interface design. Typical torque ranges between 12–16 Nm to ensure sufficient preload without deforming module frames.

Q: How does module frame thickness affect clamp selection?

A: Clamp height must match module frame thickness precisely. Incorrect sizing may lead to under-clamping or excessive pressure, both of which can compromise structural reliability.

How Should Solar Mid Clamps Be Selected and Installed for Different Applications?

Selection of Solar Mid Clamps begins with understanding the PV system configuration, including rail type, module frame dimensions, and environmental exposure conditions. Ground-mounted systems often prioritize higher wind resistance, while rooftop installations emphasize ease of installation and weight optimization.

Installation best practices require alignment checks before final torque application. Uniform tightening sequence across the array helps prevent uneven stress distribution. Compatibility with aluminum rails and grounding continuity must also be verified to ensure electrical safety compliance.

How Is the Role of Solar Mid Clamps Evolving in Future PV Systems?

As photovoltaic systems transition toward higher power-density modules and thinner frames, Solar Mid Clamp designs are adapting with adjustable heights, integrated grounding pins, and pre-assembled fastening units. These developments reduce on-site labor time while maintaining compliance with evolving international standards.

Manufacturers are also aligning clamp geometries with automated installation tools, enabling faster deployment in large-scale solar farms.

Industry References

- IEC 61215: Terrestrial photovoltaic modules – Design qualification

- UL 2703: Mounting Systems, Mounting Devices, Clamping/Retention Devices

- Solar Energy Industries Association Technical Guidelines

Within this evolving landscape, CYC Energy continues to focus on precision-engineered Solar Mid Clamp solutions that align with global PV mounting standards and installation practices. By emphasizing material consistency, dimensional accuracy, and application-driven design, the brand supports long-term system reliability across diverse solar projects.

For detailed specifications, application guidance, or project-based support related to Solar Mid Clamp solutions, contact us to engage with a technical team prepared to assist across design, procurement, and deployment stages.