How Are PV Solar Cables Selected for Different Photovoltaic Installations?

2026-01-04

Abstract

PV Solar Cable plays a critical role in photovoltaic power generation systems by ensuring stable energy transmission, long-term durability, and operational safety under demanding environmental conditions. This article provides a comprehensive analysis of how PV Solar Cables are selected for various installation scenarios, focusing on technical parameters, international standards, and real-world applications. By examining material composition, electrical performance, compliance requirements, and installation practices, this guide offers a structured and practical reference for decision-makers involved in solar energy projects.

Table of Contents

- How Do PV Solar Cables Support Modern Photovoltaic Systems?

- How Are Technical Parameters of PV Solar Cables Defined and Evaluated?

- How Do PV Solar Cables Perform Across Different Installation Environments?

- How Will PV Solar Cable Technology Evolve with the Solar Industry?

Outline

- Role and fundamentals of PV Solar Cables

- Key technical parameters and standards

- Installation environments and performance requirements

- Future development and market direction

How Do PV Solar Cables Support Modern Photovoltaic Systems?

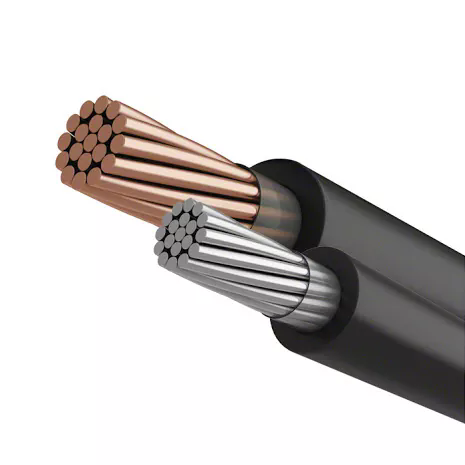

PV Solar Cables are specifically engineered electrical conductors designed to interconnect solar panels, inverters, and combiner boxes within photovoltaic systems. Unlike conventional power cables, these cables are built to withstand continuous exposure to ultraviolet radiation, extreme temperature fluctuations, ozone, moisture, and mechanical stress. Their primary function is to transmit direct current (DC) electricity generated by solar modules with minimal energy loss and maximum safety.

In grid-connected, off-grid, and hybrid photovoltaic systems, PV Solar Cables ensure consistent electrical performance over service lifetimes that often exceed 25 years. The selection process is therefore not limited to conductor size alone, but also includes insulation materials, voltage ratings, fire resistance, and compliance with regional regulations.

As photovoltaic installations expand from residential rooftops to utility-scale solar farms, PV Solar Cables have become a foundational component that directly impacts system efficiency, maintenance costs, and overall project reliability.

How Are Technical Parameters of PV Solar Cables Defined and Evaluated?

The performance of a PV Solar Cable is determined by a combination of electrical, mechanical, and environmental parameters. These specifications are standardized to ensure compatibility with photovoltaic equipment and compliance with safety requirements across global markets.

Key Product Parameters

| Parameter | Specification Range | Technical Significance |

|---|---|---|

| Conductor Material | Tinned Copper | Enhances corrosion resistance and conductivity |

| Nominal Voltage | DC 1.5 kV / AC 1.0 kV | Supports high-voltage photovoltaic strings |

| Temperature Range | -40°C to +120°C | Ensures stable operation in extreme climates |

| Insulation Material | XLPO / XLPE | Provides UV resistance and thermal stability |

| Service Life | 25–30 Years | Matches photovoltaic module lifespan |

These parameters are evaluated against international standards such as IEC 62930, EN 50618, and TÜV certifications. Compliance ensures that the PV Solar Cable can operate safely under continuous load while resisting degradation caused by environmental exposure.

PV Solar Cable Common Questions and Answers

Q: How does a PV Solar Cable differ from a standard DC power cable?

A: PV Solar Cables are designed for long-term outdoor exposure, featuring enhanced UV resistance, ozone resistance, and extended temperature tolerance that standard DC cables do not provide.

Q: How is the correct cable cross-section determined for a solar project?

A: Cable sizing is calculated based on current load, system voltage, installation length, and acceptable voltage drop, ensuring optimal efficiency and safety.

Q: How long can PV Solar Cables operate without performance degradation?

A: When manufactured to international standards and properly installed, PV Solar Cables can maintain stable performance for over 25 years.

How Do PV Solar Cables Perform Across Different Installation Environments?

PV Solar Cable performance varies depending on installation conditions such as rooftop systems, ground-mounted solar farms, desert installations, and floating photovoltaic platforms. Each environment introduces unique mechanical and environmental stresses that influence cable selection.

In rooftop installations, flexibility and fire resistance are critical due to space constraints and building safety regulations. Ground-mounted systems prioritize mechanical strength and resistance to soil moisture and rodents. Desert environments demand exceptional UV and heat resistance, while coastal and floating systems require enhanced resistance to humidity and salt corrosion.

The adaptability of PV Solar Cables across these environments enables consistent system output and reduces the frequency of maintenance interventions over the system lifecycle.

How Will PV Solar Cable Technology Evolve with the Solar Industry?

As photovoltaic technology advances toward higher system voltages, increased power density, and smarter energy management, PV Solar Cables are also evolving. Future development trends include improved insulation compounds, reduced conductor resistance, and enhanced recyclability to support sustainability goals.

In addition, digital monitoring integration and compatibility with next-generation inverters will influence cable design standards. These innovations aim to improve overall system efficiency while maintaining strict safety and compliance benchmarks.

In this context, DAYA continues to focus on manufacturing PV Solar Cables that align with international standards and evolving market requirements, supporting photovoltaic projects across residential, commercial, and utility-scale applications.

For project-specific requirements or technical consultations regarding PV Solar Cable selection, please contact us to receive detailed support and customized solutions tailored to your photovoltaic installation.